Tube Beading Tools

Medium Tube Beading Tool, 3/8", 1/2", 5/8" O.D. Tube

Medium Tube Beading Tool, 3/8", 1/2", 5/8" O.D. Tube

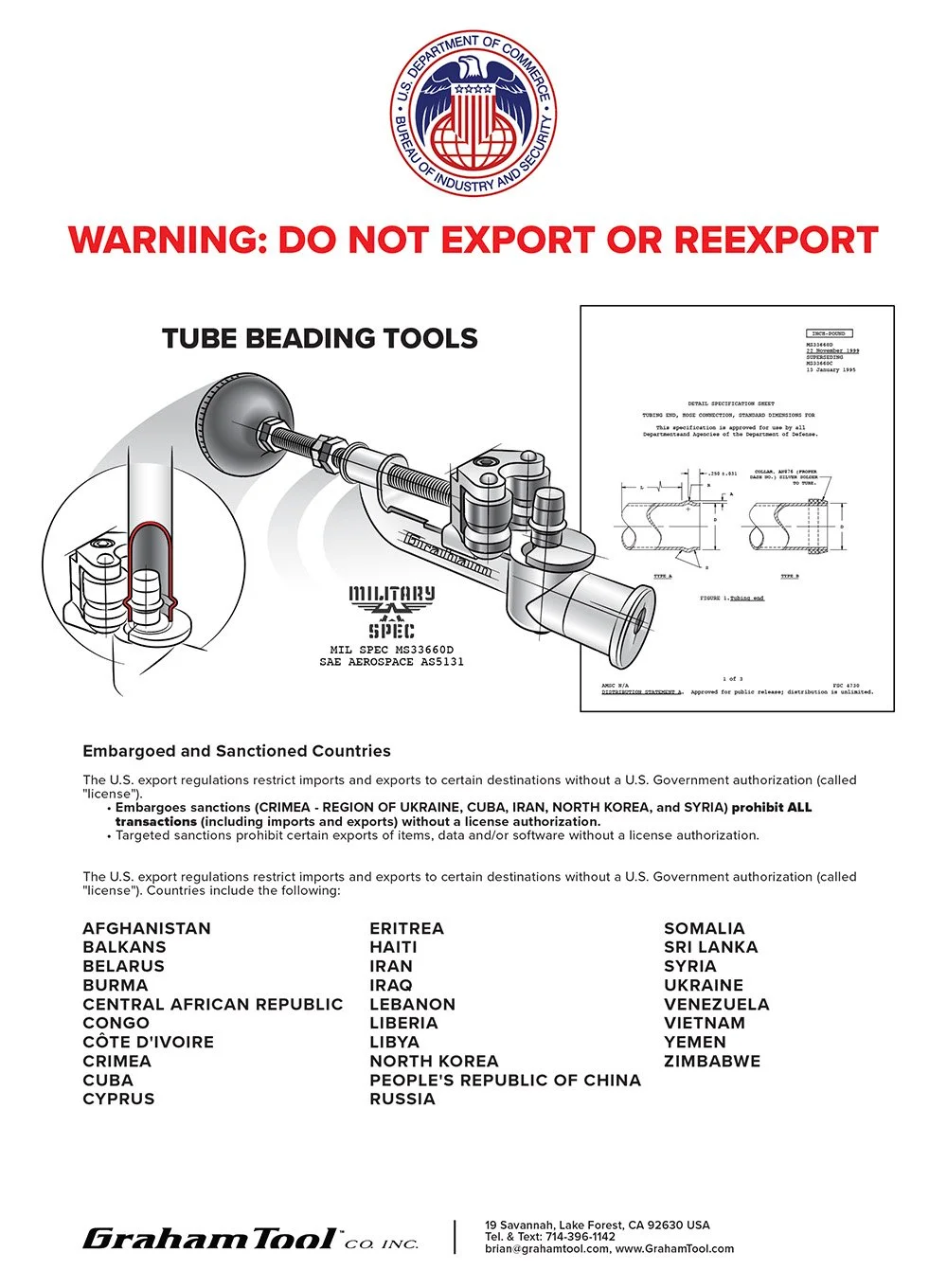

Designed in the USA during WWII for aircraft applications. This United States Military Specification item cannot be exported or reexported to countries subject to embargo or sanctions (refer to the list provided in the accompanying images). It is a proven tool with a long history. Available to the public by popular demand. Manufactured in California using 100% USA materials. Useful to form a bead on rigid tubing for hose and hose clamp applications. Works on 3/8", 1/2", and 5/8" O.D. tubing. Can be used on aluminum, copper, steel, and stainless steel. Heavy duty inner and outer rollers are made from H11 tool steel to be used on stainless steel applications.

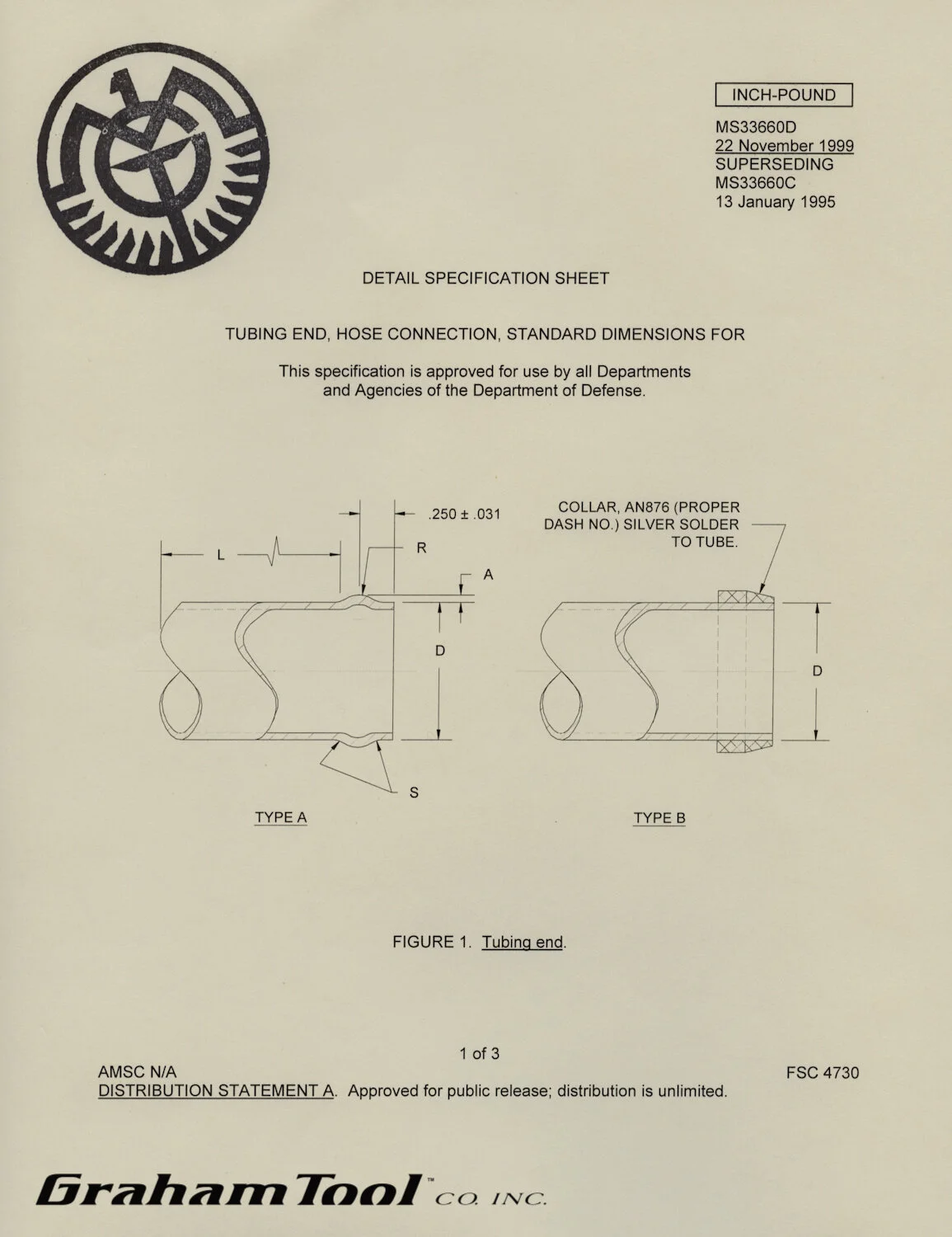

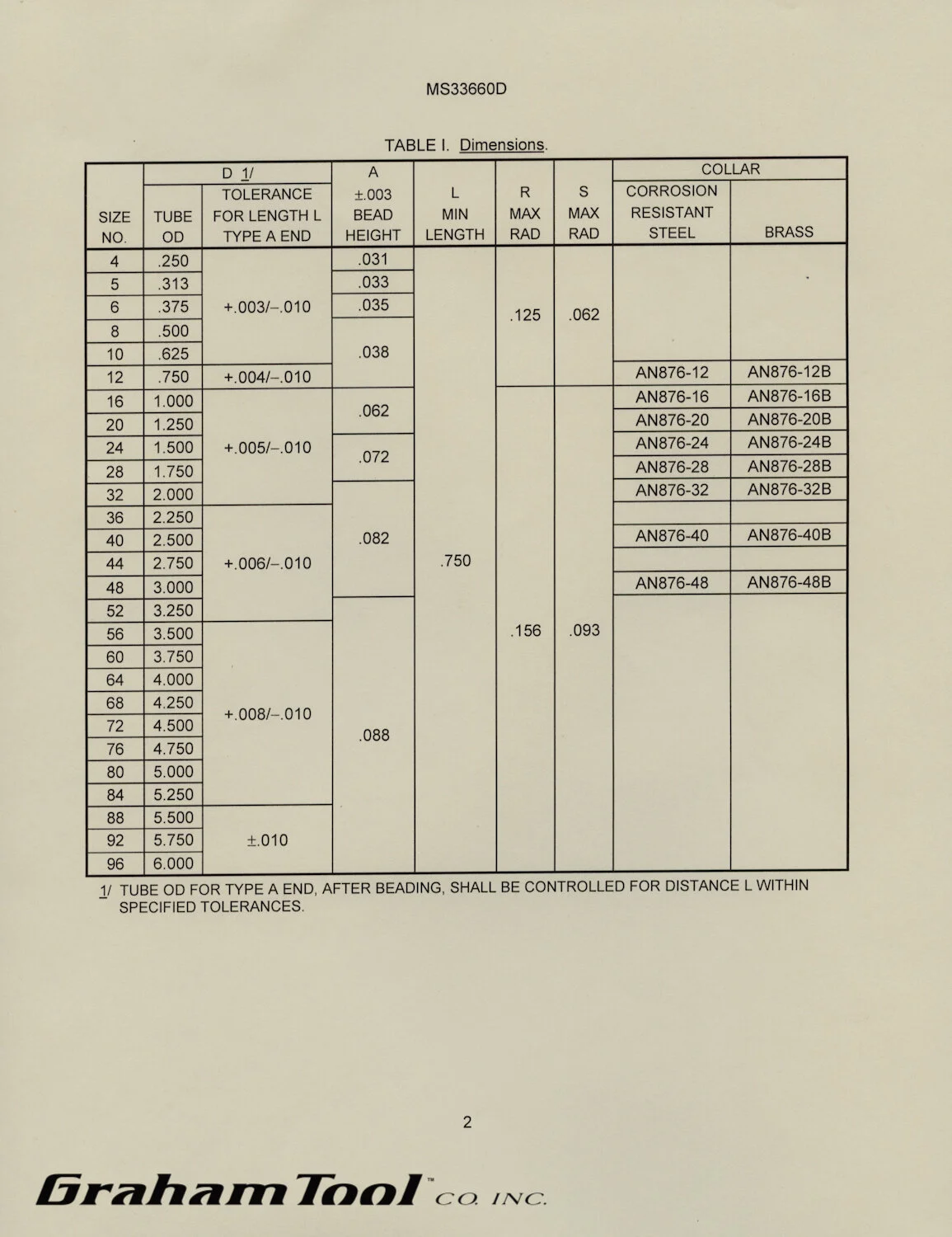

Our customers include Boeing, Los Alamos National Laboratory, US Marines, US Army, Sandia National Laboratories, United Launch, Spawar, and SpaceX. Creates a bead per mil-spec MS33660D (see photos) and SAE Aerospace AS5131.

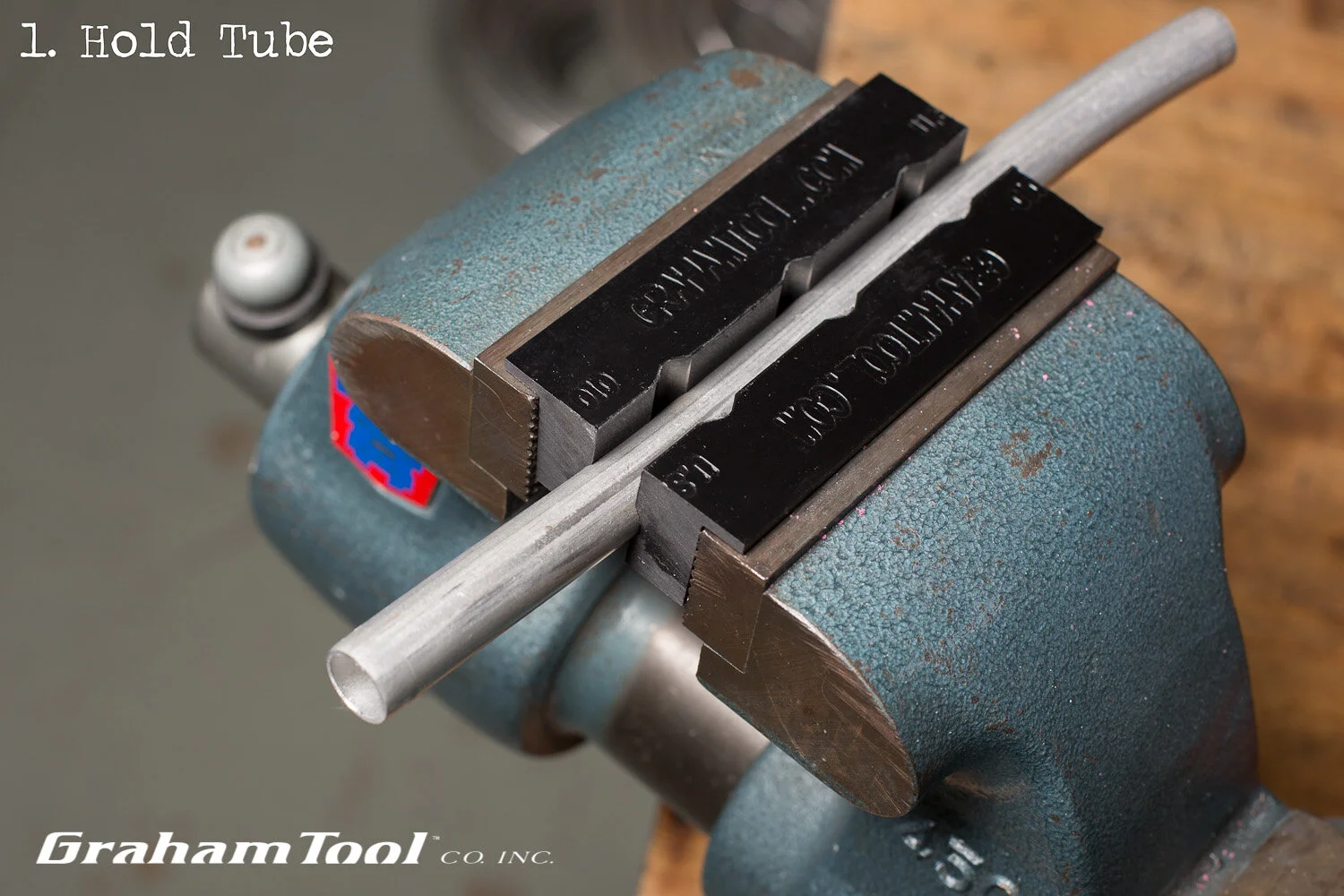

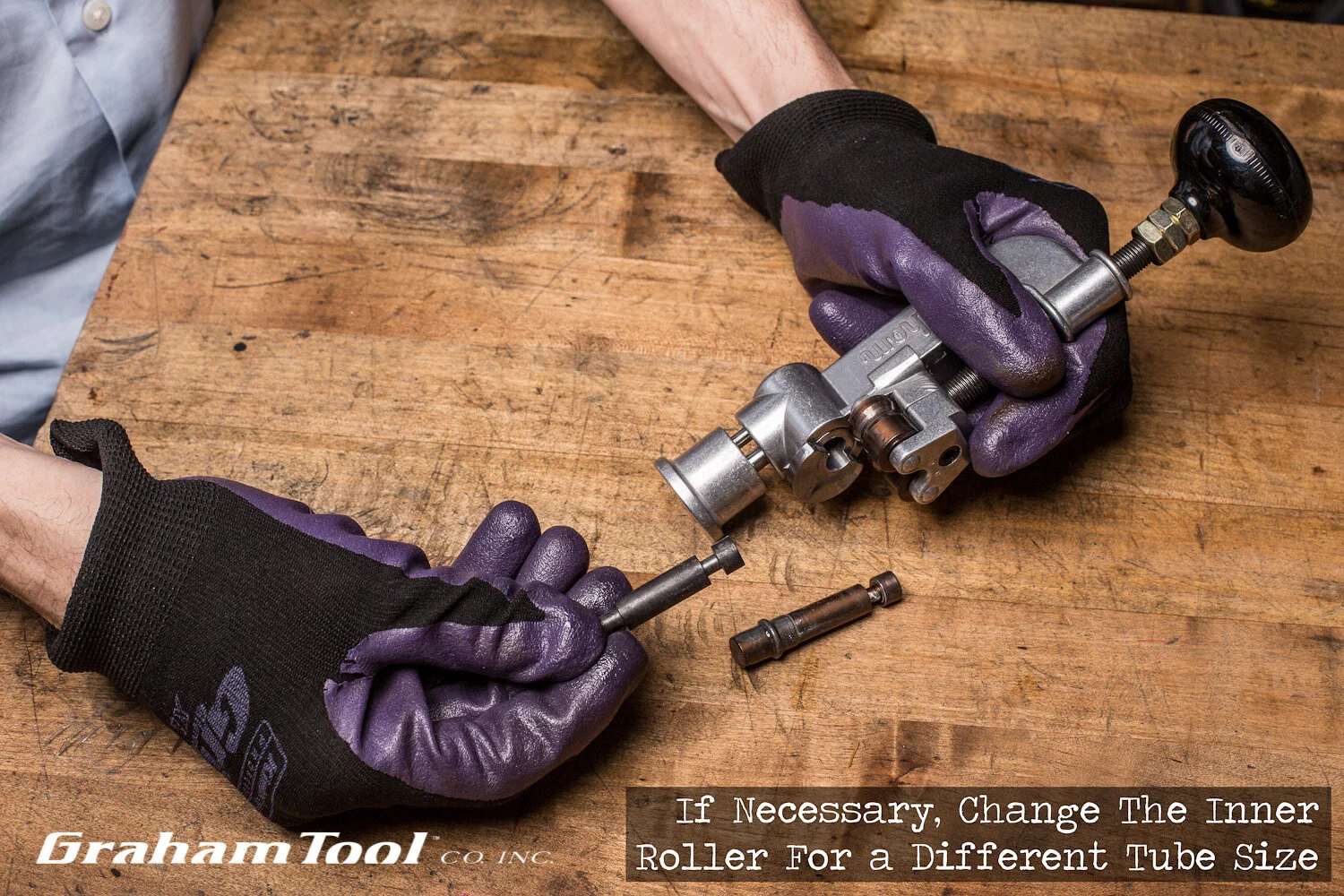

Simple to use. Step 1. Place tubing in vise v-block or field service holding tool (not included) and cut to length with a tubing cutter. Step 2. Deburr the I.D. and O.D. Step 3. Oil tube. Step 4. Install the tool, tighten the knob, and start the bead. Progressively tighten the knob with each 360 degree rotation.

Common Question:

What is the thickest wall that can be used in regard to 3/8” OD tube? Answer: The 3/8” inner roller measures .275” (see last photo) and must have clearance to both form the bead and extract from the tube after the bead is formed. As such, a 3/8” OD tube with a .035” wall has an ID of .305” (take the OD dimension and subtract double the wall thickness to get the ID). As such, .035” is about the limit. However, if you have an application that demands a thicker wall or requires material that is tough to bead, contact Brian (714) 396-1142, brian@grahamtool.com